Molding & Casting

The longest week...

I started early this week, thinking I would try to finish everything by Friday... or Saturday at the latest. Thank goodness I started when I did, because man did everything go wrong this week. The design wasn't difficult at first, just time intensive in order to get it exactly how I wanted it. The following was my inspiration and corresponding design of the wax on Rhino.

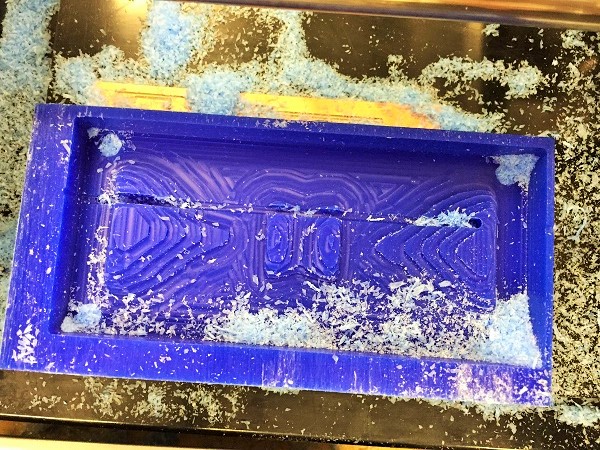

Next was the wax. Everything went well until the finishing cut. Unfortunately the mill decided my finishing cut should actually just continually put a gash through the middle of my design. The toolpath design went haywire when I tried to change the tip to a ball-end. I still don't know why this happened, but I realized the time it would take to re-do this, it would make more sense to just do it on the shopbot.

The shopbot had its own issues, but after four TAs check it out, we finally realized that one of the emergency stops on the side of the bot had been pulled out. This was causing errors in the system which delayed the proejct another two hours. Then the set up in mastercam was wrong, which ended up breaking bits until the TA figured out that the spindle speed was 10x less than it should have been. Finally, after getting the shopbot up and running and figuring out the many small modifications to the file, the shopbot worked its magic.

Next up was pouring the silicon and that was simple enough.

.jpg)

Next up was pouring my material into the silicon. But wait, I need to lasercut a box for that?

Ok, I've got the box and the silicon, now I can pour it... But wait, I need a funnel?

Ok, now it's time to pour my mold. But I have this great idea to do a clear bow tie with marbling effects! So, I ask the TAs the type of casting material I need and they recommend clear casting resin. So, I make my trip to Blick to purchase the resin and the dye to create the marbling effect.

Then I mixed it together following the directions and waited.

Well, after 24 hours I realized the whole thing was a bust. The resin wasn't right and it had seeped out the sides of the silicon anyway. So much for trying to get cool... I should have just stuck with the hydrostone!

And now for the hydrostone result

.jpg)

.jpg)